One of the Non-Vessel Operating Common Carriers from Oman connected us to make their Ocean Freight business. The client was aiming to have a digital solution that simplifies multi-shipment handling, lot management, and cargo planning. After understanding our client’s requirement, we suggested them to create an AI-backed ERP platform that offers on-time visibility. When the new solution was implemented, our client experienced swift operations, zero downtime, and control over their freight operations.

The system at the client side was not so connected internally. It was causing slower updated, poor route visibility, and they could not make decisions. Another hurdle they were facing was poor coordination between carriers.

Since there were multiple lots, monitoring each one of them was a difficult task. It created confusion and duplication mistakes. As a result, it made the operations slower and created gaps between financial and operational records.

A huge cargo planning and container utilization was done manually and without automation. Due to this challenge, there were underfilled containers, high costs, and time-consuming allocation.

Since the client was having outdated systems, integration was becoming a challenge. The data was exchanged manually that has caused delays and human errors.

Since everything was manually dependent, preparing and validating shipping documents was a tough task. Besides, manual handling of documents increased compliance risks and made the clearance slower.

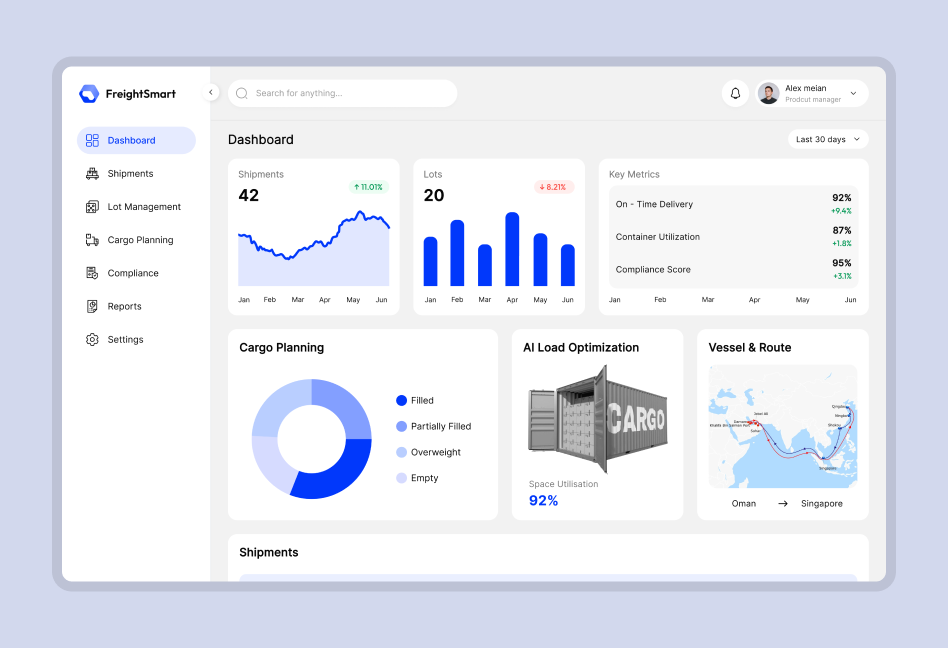

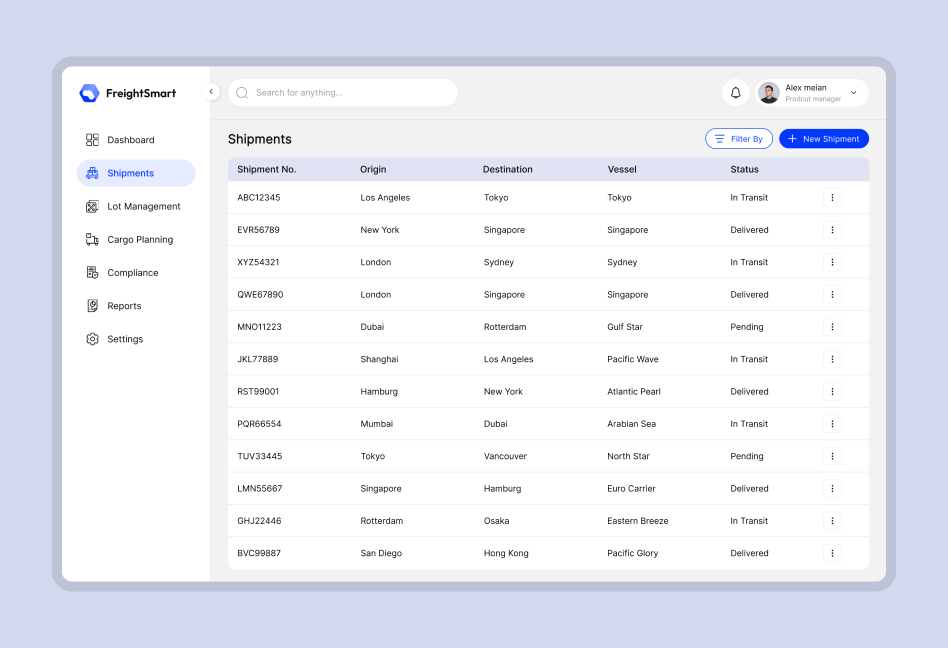

We created an ERP system that brought freight, lot, and cargo under single digital platform. With this system, the teams can have a lot at the dashboard and make decisions. Also, they used to collaborate seamlessly and get access to insights without much hassle.

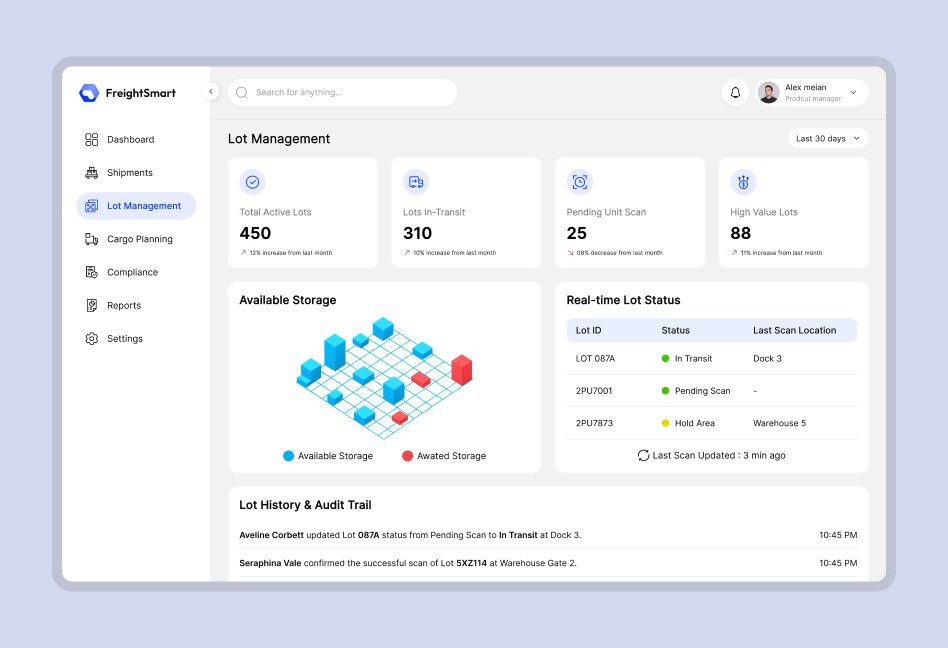

Since our client was aiming for automation, we automated the lot management process. Now their teams can easily create, monitor, and document several lots altogether. As a result, there are zero errors and better precision.

Our AI-powered engine evaluated cargo load distribution and space utilization across containers. With predictive algorithms, our client is now able to analyze shipment data and minimize idle capacity. As a result, they are having faster turnaround times and significant cost savings in cargo operations.

The client also wanted secure and scalable API integrations to connect the ERP with port authorities, customs, and partner systems. It made sure smooth data exchange, real-time updates, and end-to-end visibility across the logistics chain. With this integration, they noticed improved compliance reduction in reduced delays.

Our solution also includes a feature that has helped our client with creating and validating shipping documents, including bills of lading, manifests, and invoices. The system abides by international trade and maritime regulations without much manual involvement. It reduced processing times and upgraded the accuracy of every document generated.

It helped with centralized monitoring that offers detailed visibility across multi-shipment operations. Teams could easily make data-driven decisions with better route and cargo insights.

With automation, manual data entry and paperwork were replaced across departments. Several processes that used to take hours are now completed within minutes.

With the use of AI, container utilization and shipment sequencing became easier. As a result, clients faced quicker turnaround times and seamless cargo management.

Since we streamlined workflows, our client noticed elimination of redundant systems and manual inefficiencies. As an outcome, the client gained measurable savings and better resource allocation.

We created intuitive design and offered structured training that resulted in rapid system adoption. The teams at client side adapted quickly and enabled consistent efficiency across all freight operations.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy