Our client is a Danish company that is involved in airways and ocean freight logistics business, and that handles high-volume cargo traffic between ports, warehouses, and transit sites in Asia, Europe, and North America. They deal with containerized cargo, checking of inventory, loading, and unloading, as well as keeping records in areas where traditional systems or laptops are not applicable because of space and mobility. To facilitate these on-ground logistics processes, the client needed a warehouse management solution that was intended to record inventory in real-time and at Ports location.

The concept was straightforward: ease the processes of cargo operations for the people on the ground. Teams required an expedited method of taking inventory, checking container details, and reporting problems at the location of work, not moving back to a desktop computer and using a cumbersome system to slow down their work. Meanwhile, the solution needed to be versatile in terms of freight types and locations, as well as accessible to global teams.

Laptops and large systems are not applicable in the warehouse yards, ports, and container zones. There was no feasible method of getting inventory information at the point of the container, and this resulted in delays and reliance on handwritten records.

The weight of the containers, dimensions, and lot information of the inventory were manually captured and then entered into systems. This procedure augmented the possibility of data inconsistency, blanketing records, and ineffectiveness.

The client had a problem with monitoring cargo reception, loading, and stock condition live. This rendered it challenging to track the progress of containers and address the operational change swiftly by the teams.

There was no formal mechanism for reporting received shortages or missing items during the devanning process when there were shortages in cargo quantities received or with missing items, and consequently, there was no effective traceability and speedy resolution of the issue.

The solution that we came up with was aimed at making the work in warehouses and cargo simpler in the difficult conditions of ports and off-site. We had to make sure that we were mobile, real-time visible, and operationally accurate, as well as allowing easy cargo handling and inventory tracking throughout air and ocean freight operations. Here are a few things that we took care of.

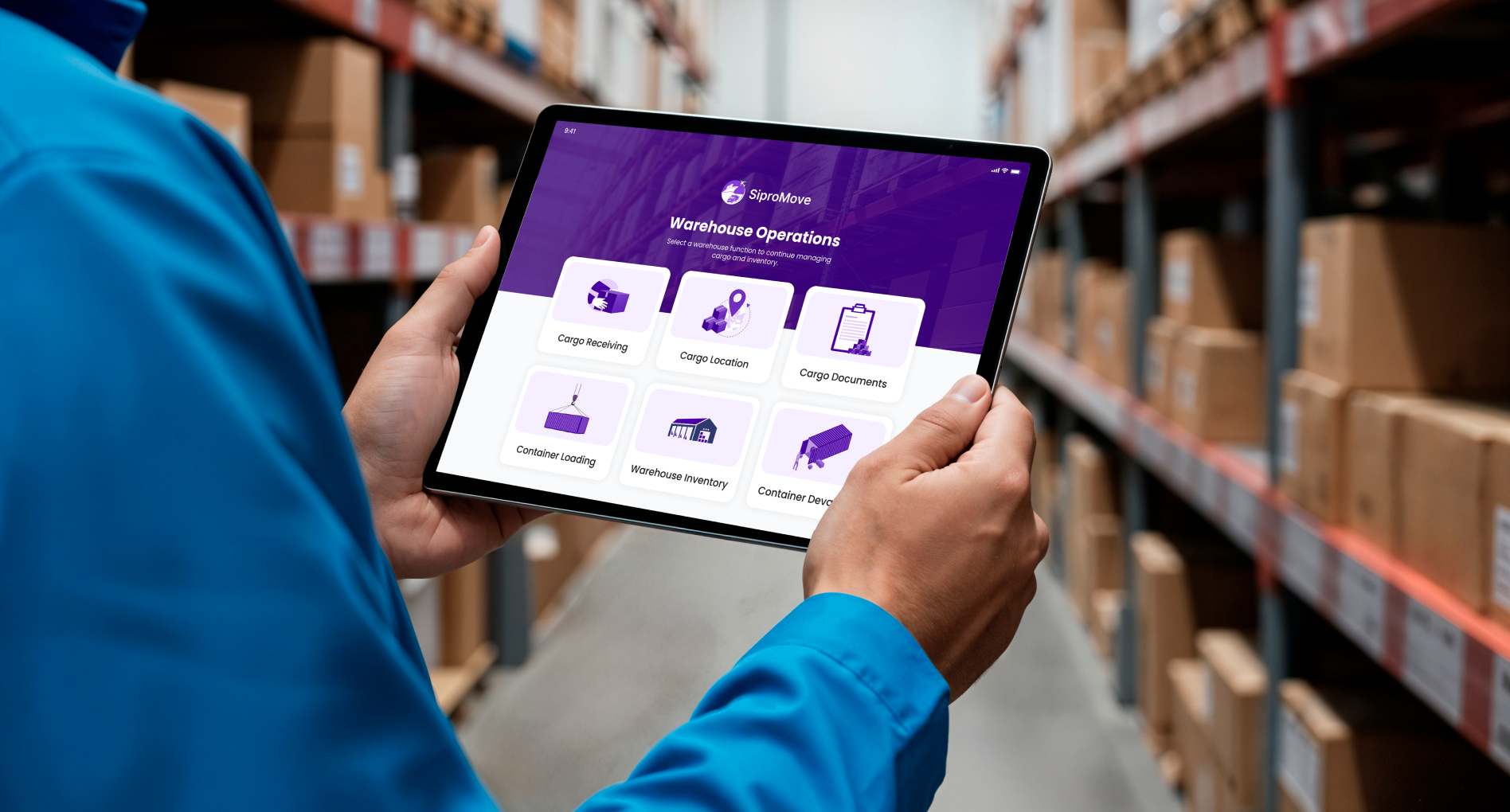

We built a mobile application that is highly tailored to use with iPad so that we can minimize the need to carry extra devices in the warehouse which is not possible in off locations. It is challenging to bring big devices or systems in the port location. Moreover, the app is specifically made to run on iPAD only.

The system allows the user to record the details of containers like weight, height, dimensions, and location in real time, thus having precise and current records of inventory.

The solution gives full access to cargo receiving, loading, offloading, and warehouse inventory in both air and ocean freight business processes with specific modules.

Our cargo devanning feature, which enables users to record shortages, missing ones, or discrepancies during receiving, enhances accountability and traceability.

The teams in the warehouse do not have to stop working to input data in the future. Data is recorded during the real cargo handling process, which assists employees in the transportation of containers and shipments without any delays.

The client also saved a lot of time previously used to correct inconsistencies by having accessible and reliable data at the beginning, hence reducing a lot of follow-ups, corrections, and cross-checks among teams.

Air/Ocean cargo teams are now able to go through a standard process, which minimizes confusion and enhances coordination, as well as makes new staff feel at ease with the day-to-day operations.

Any deviations are highlighted when they arise, and as a result, the supervisor is able to take immediate action rather than investigating issues once the shipments are in motion.

The system is built to support multiple languages, making it ready for future global operations without additional system changes.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy