Our client is a mid-sized logistics and distribution company with its headquarters located in Denmark and with branches that operate numerous warehouses and a regional freight network. They were seeking to create an integrated platform that would put together their current Warehouse Management System (WMS) and Freight ERP to attain full and real-time inventory visibility at all locations. They wanted a Real-time inventory visibility with ERP.

The client wanted a WMS and ERP integration so that they can accurately and timely get inventory visibility in all warehouses and in the freight in transit.

The freight/ERP system and the warehouse management system were running in silos. One version of inventory was perceived by warehouse personnel, another by freight logistics. The WMS and freight ERP did not have a seamless real-time synchronization.

Since updates were either batch-based or manual, inventory levels were usually not up to date. This resulted in constant stock-outs or excessive stock. Industry sources state that a considerable number of warehouses have yet to achieve a consistent visibility that results in inefficiencies.

The system did not provide a real-time status of inventory in transit (in transit, stakeholder) when inventory was in motion (transport/freight). This implied lost inventory across systems

The operations were slowed due to the manual reconciliations between systems, spreadsheets, manual updates, and interventions. The client required a high-scalability and automated setup

An integration layer between the WMS and the Freight ERP systems was put in place. This involved APIs and an event streaming engine based on micro services. This layer was used to make sure that any movement of inventory in the Warehouse would automatically cause the ERP to update.

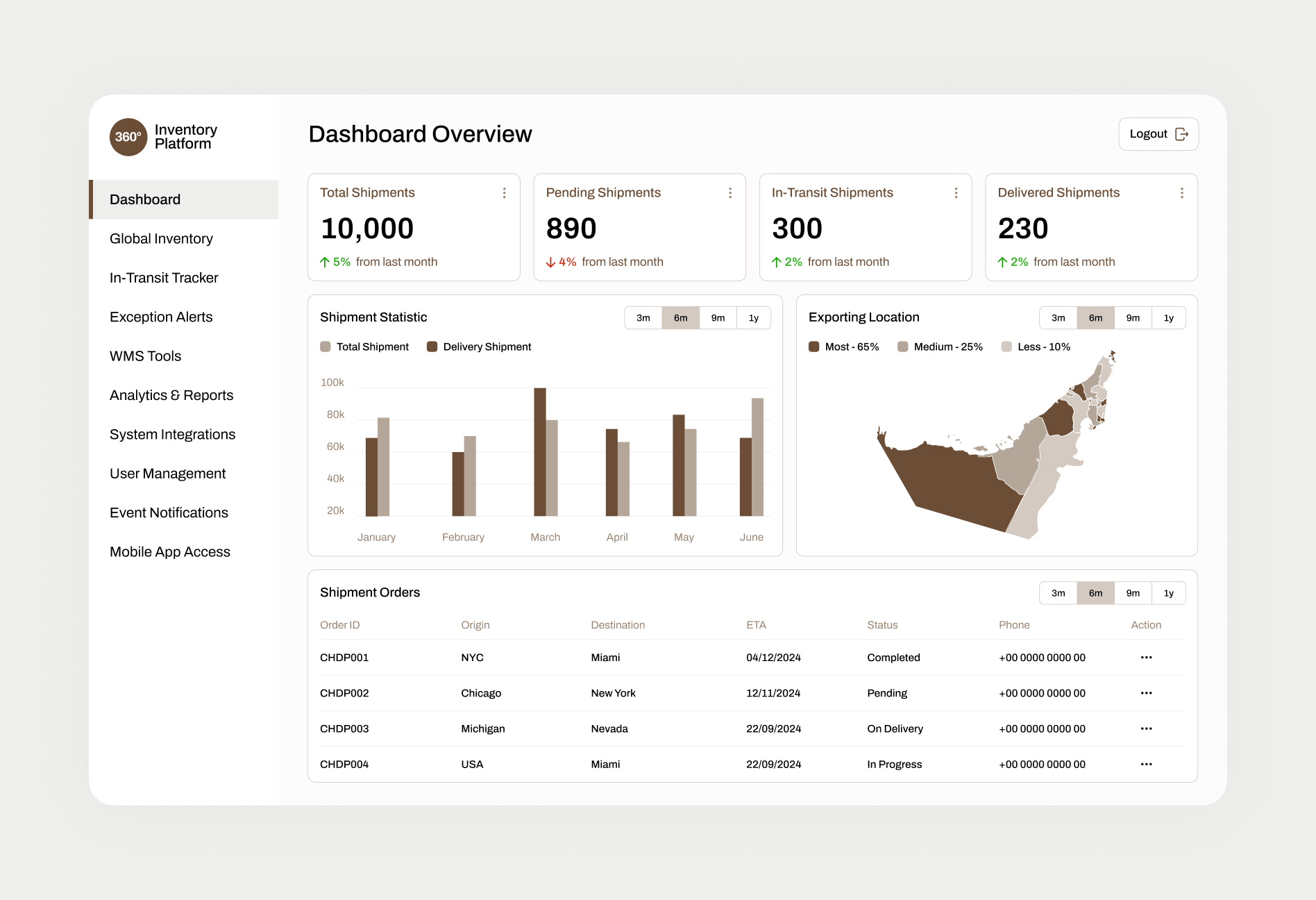

We added the real-time update functionality to the WMS: inbound, pick/pack/ship, and freight dispatch events were input into an active inventory dashboard. This enabled the statuses of physical inventory to be seen, as well as the statuses of transit and location to be seen in a single place. For real time inventory tracking we approached them for warehouse management ERP solution for which they agreed to go with.

We have added RFID/barcode scanners connected to the WMS that would automatically record inventory events (put away, picking, shipping). Freight loads were also tagged to monitor transit-in-motion status and provide it back to the ERP.

We built a dashboard for the client’s operations leadership: view live on-hand inventory, inventory in transit, status by warehouse or freight node, alerts when inventory mismatches occurred or when thresholds were reached.

We collaborated with operations, freight/transport teams, and warehouse workers to redesign work processes. Real-time scanning was required, manual reconciliation was substituted with real-time warning, the personnel were trained on the new system and dashboard.

With WMS and freight ERP having real-time synchronisation, the client experienced a substantial decrease in inventory differences. Single source of truth reduced manual reconciliations significantly.

Since inventory status (in Warehouse, in transit) is visible in real time, operations teams might be able to respond quickly to low-stock alerts or delays in transit. This resulted in reduced stockouts and higher levels of service.

The cost of operations in terms of inventory counting and reconciliation was cut by automated data capture (RFID/barcode) and less manual work. There was improved control of space utilisation and stock levels (reduced overstock).

The dashboards now provide real-time inventory at the Warehouse and the freight route. This enhanced planning, forecasting, and confidence in the data among the stakeholders.

The architecture is scalable: we can add new warehouses, new freight routes, new channels of inventory (e-commerce, omni-channel) without redesigning core sync infrastructure.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy