Our client is one of the largest shipping and logistics companies in the USA, operating in various geographies, and has a good presence in the global market. They used a Fleet ERP system to handle back-office activities, cargo, and shipments. Nevertheless, the manual data handling and warehouse processes introduced inefficiencies and delays in the day-to-day operations. To beat this, they sought to come up with a Warehouse Management App that would be integrated with their ERP system to facilitate workflows.

The client wanted to upgrade their warehouse to include a mobile-first operating system designed to interact with their existing ERP. Their key goals included:

The client's Fleet ERP system relied on the manual entry of data, which hampered the activities and made it vulnerable to the risks of errors. The process of retrieving or updating records takes a lot of time and resources.

The loaders were compelled to adopt the traditional desktop work processes to record the details of the cargo. This made it difficult to upload images, update the size of various cargoes, and monitor the shipment information.

The ERP was developed mainly to be used in the back office, leaving loaders and warehouse staff with no mobile access. Such incompatibility of devices and systems led to delays in updating records and a lack of the real-time flow of information.

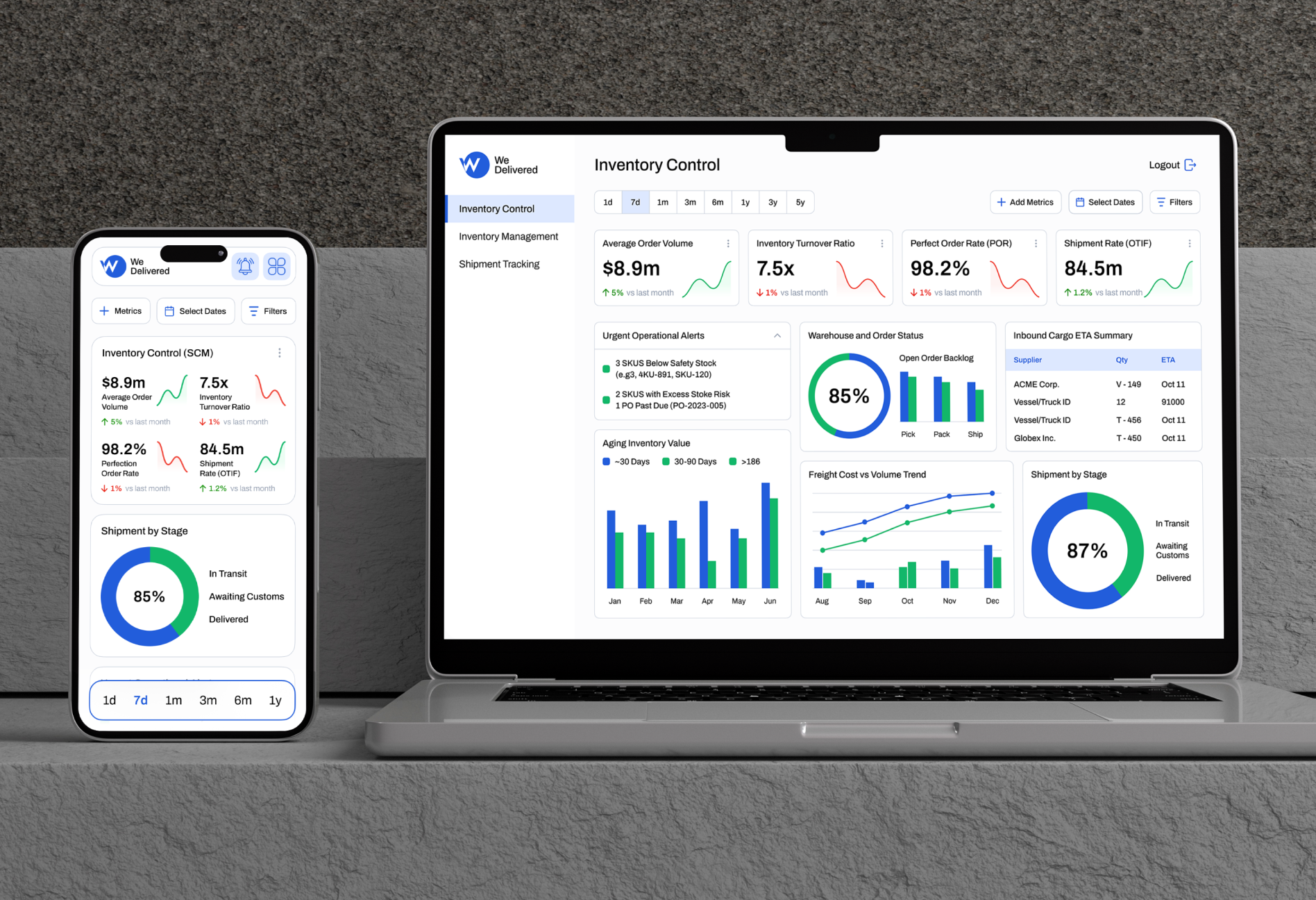

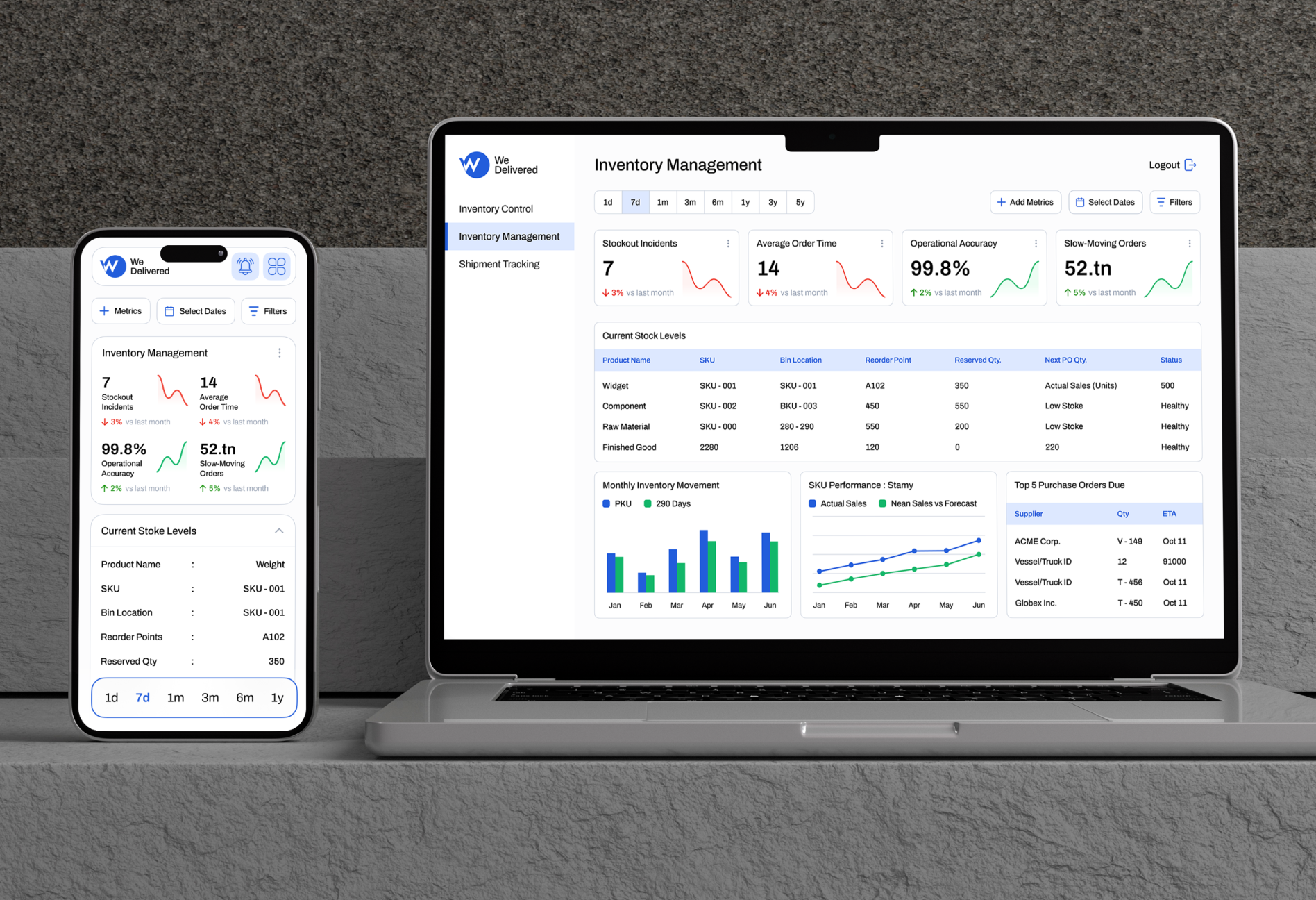

The ERP system did not have built-in analytics to produce insights or a performance report. The development of management-level dashboards was very manual, and the decision-makers were deprived of the chance to get real-time and accurate data.

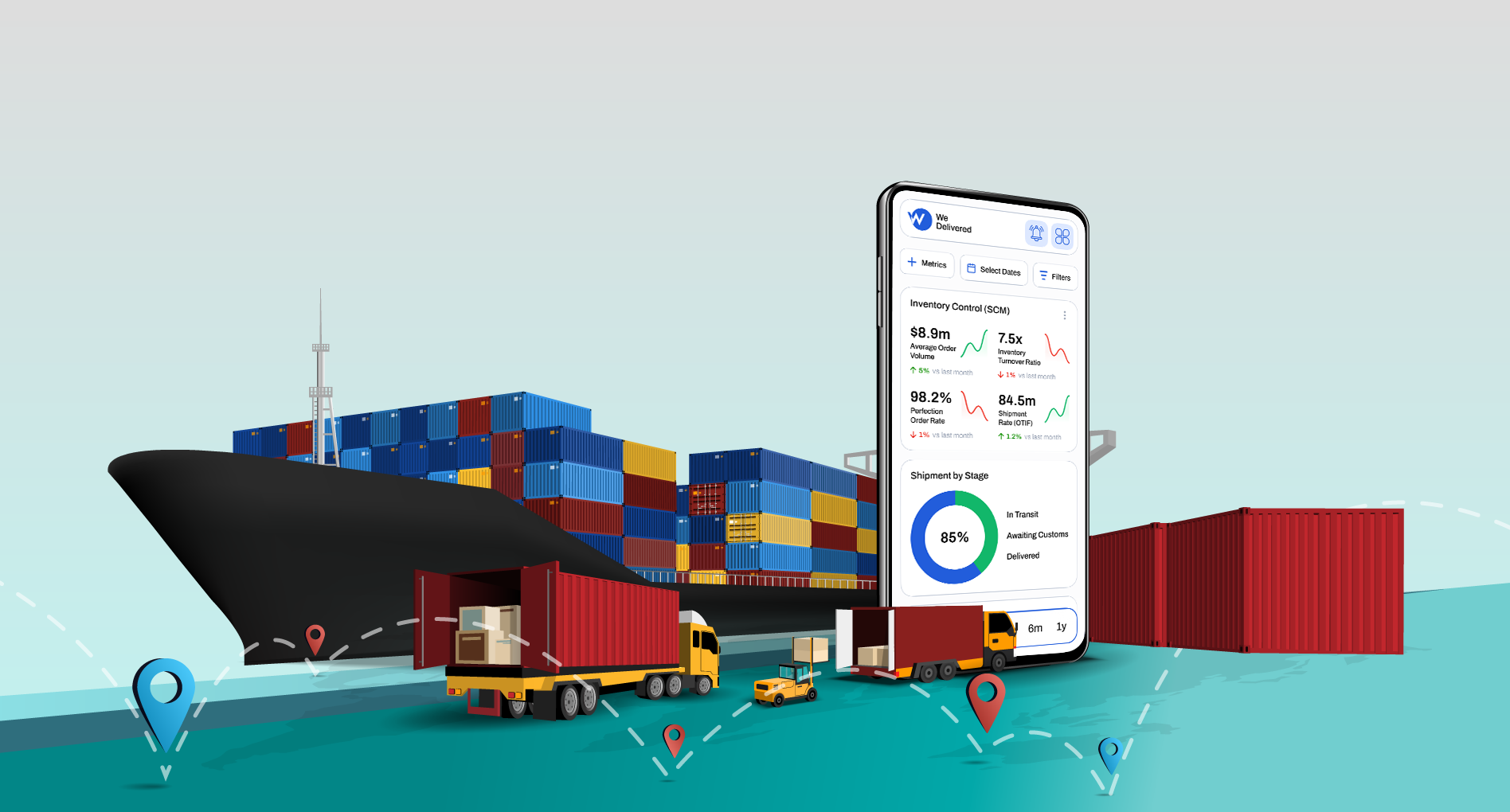

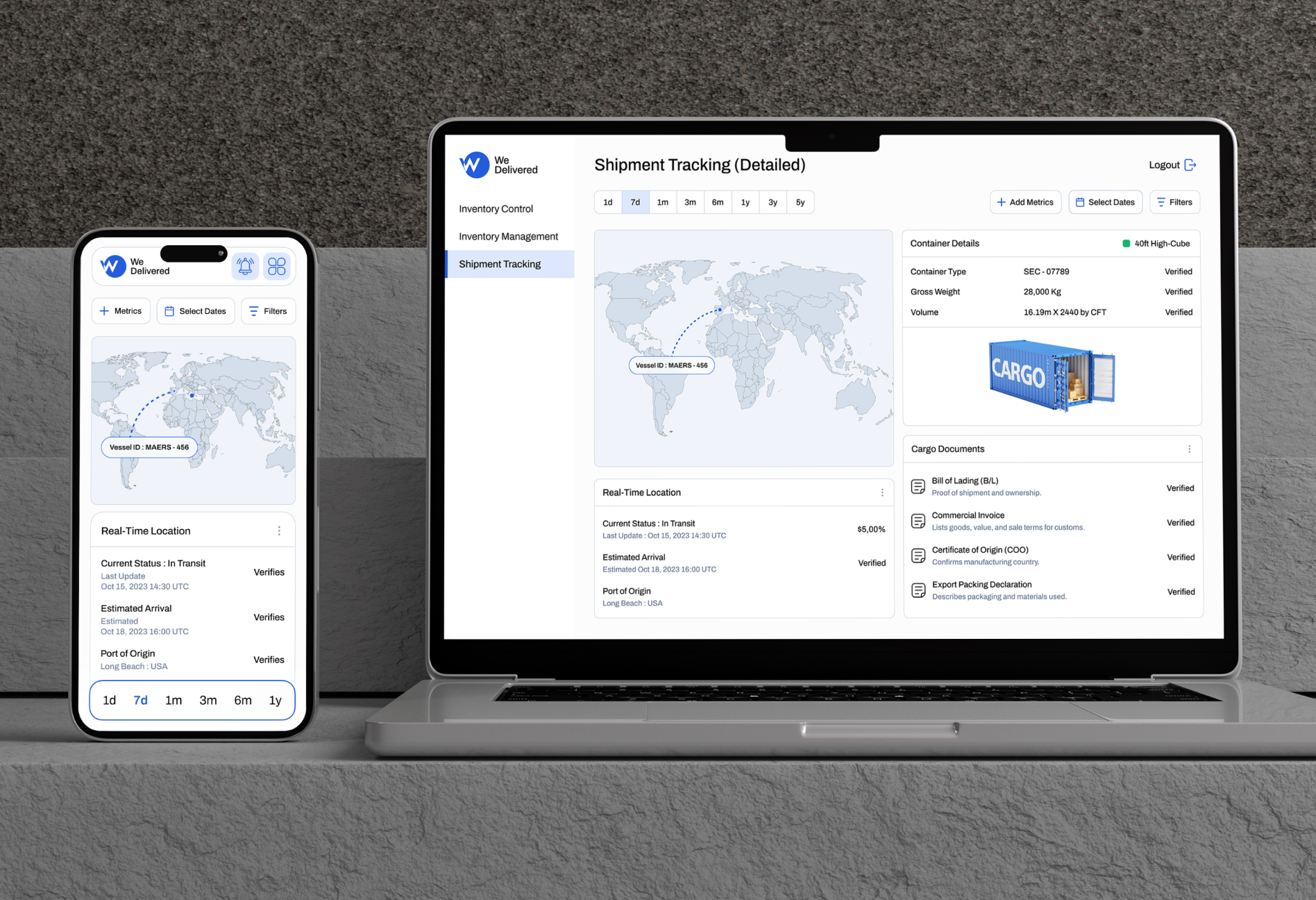

We designed a Warehouse Management App (WMA) that had a close connection to one of the existing Fleet ERP systems of the client. This provided real-time coordination of cargo information, which removed manual updates and ensured accuracy in the information at all touchpoints.

The app enabled the loaders and warehouse personnel to carry out major tasks, including scanning the lot number, updating the cargo information, and uploading an image, using only mobile devices.

Using REST API, Spring, Core Java, and iOS technologies, the solution allowed immediate updates of devices and systems. This facilitated information flow throughout the warehouse floor to the back-office ERP.

We also incorporated a Performance Analytics module to deliver automatic insights into app performance, such as crash reports, connectivity status, error logs, and usage data. These insights helped them make real-time decisions at the right time.

The application made the work in warehouses much easier. The WMS solutions eliminated the manual mistakes and guaranteed a well-organized cargo flow.

Secondly, Fleet ERP was used to provide users with instant access to any data in any location. It increased their responsiveness and helped them make better decisions.

The solution gave more visibility into the warehouse inventory and cargo. It helped them maintain transparency.

Document management became faster through digital management and enhanced the efficiency of operations.

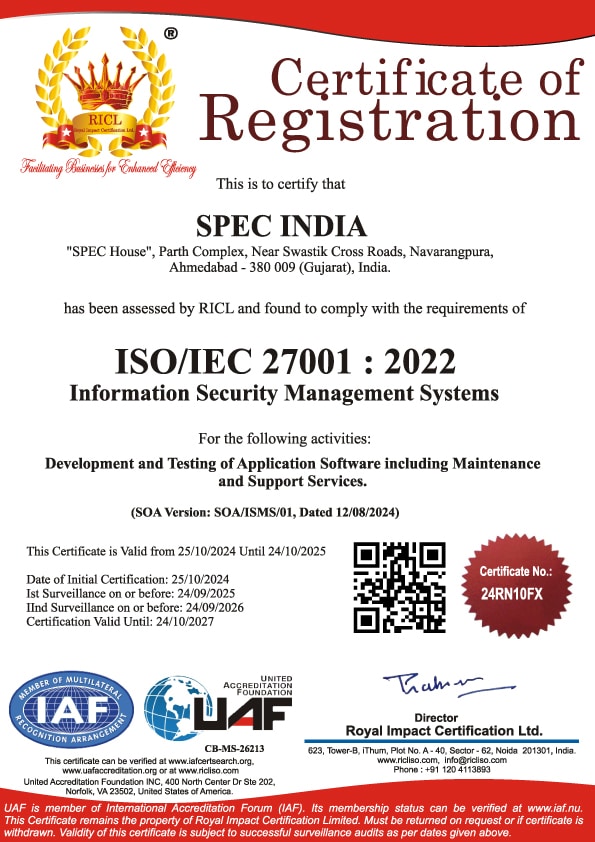

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy