Struggling to manage day-to-day warehouse operations or facing challenges in keeping everything organized? Deploy an established and scalable enterprise warehouse management system designed to meet real-world warehouse scenarios. Get live data on inventory, location, and movement of stocks. Make picking, packing, and dispatching simpler. Minimize human mistakes and errors. Enhance the precision of orders and the speed of delivery, fully without the effort, cost, and risk of building it from scratch.

To operate a warehouse today, it takes more than storage. It requires precision, speed, and real-time visibility. Our Warehouse Management System provides you with the ability to manage inventory, locations, and warehouse operations at one centralized location. Monitor all the movements in real time. Receiving and putting away through picking, packing, and dispatching. If you are an enterprise replacing legacy WMS, then this WMS solution is just for you.

Have full visibility of stock levels and order status. Minimize inventory mistakes, time wastage, and paperwork. Automate the work processes in the warehouse every day and unify the workflow in one centralized platform. Enhance the accuracy of picking and expand your warehouse operations with ease as your business expands with our WMS inventory management system.

What you can achieve with our WMS software:

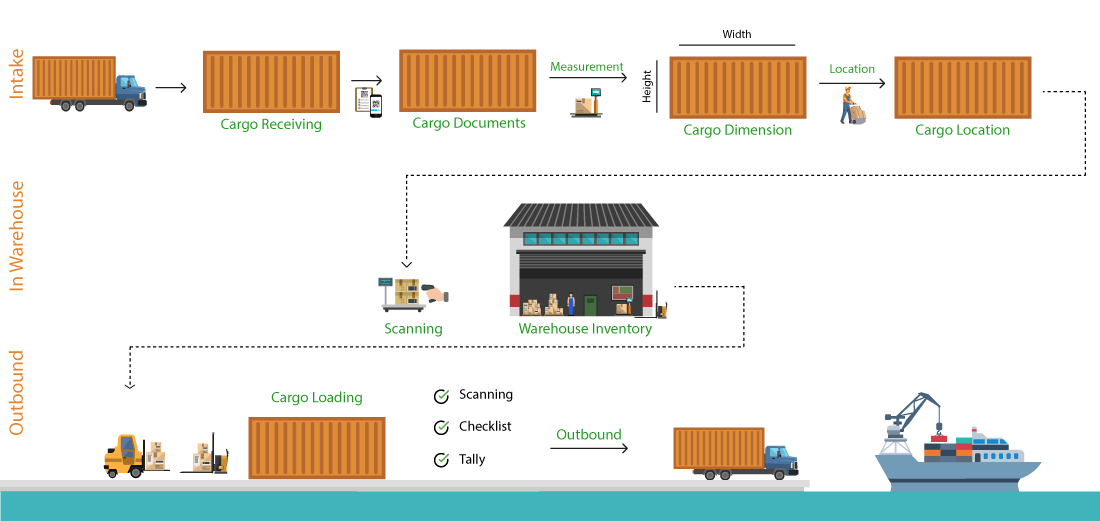

Have full operational control over your warehouse network. Our warehouse management system can control the movement of inventory, warehousing sites, and the daily operations of the warehouse. All the stocks are recorded at the transaction level. This guarantees increased inventory accuracy and enhanced execution of inbound and outbound operations, which is important for today’s businesses.

Mobile-driven execution is an empowerment tool for your warehouse workforce. We facilitate barcode-based operations that make warehouse teams communicate with the system in real time. There is improved performance in the execution of the tasks, reduced errors, and adherence to workflows.

Transform the data of the warehouses into actionable intelligence. Our WMS has real-time performance and analytics to assist in tracking operations, determining inefficiencies, and making informed decisions more quickly. Our warehouse management system can be used easily by the workforce without getting much training because we have focused more on its user friendliness.

Transform the data of the warehouses into actionable intelligence. Our WMS solutions offers real-time analytics and performance dashboards to make operations monitoring more convenient for the staff. You can also determine inefficiencies and errors, if you have any, and make informed decisions more quickly.

Ensure smooth data flow throughout your supply chain ecosystem. Our expert developers better understand business-changing requirements and warehouse operation needs, hence the core of our WMS is integration-ready. Our enterprise warehouse management system cop up easily with ERP, TMS, and external systems without any interruption. It even ensures data consistency and continuity in operations.

Our WMS would support you to expand your business without interruption, as it is designed to expand alongside the business. The cloud-based WMS architecture guarantees performance, security, and compliance even on a large scale. All your information is secure at all levels. Through this we ensure with our own AI infrastructure set up through which we assure data privacy and accuracy.

Industries are putting warehouses under continuous pressure to minimize inventory expenses, maximize space, assure order accuracy, and enhance workforce productivity. The Warehouse Management System (WMS) that we offer overcomes these issues by providing pre-industry workflows that can provide instant value to operations without the need to customize them. The WMS solution is designed to support retail, logistics, FMCG, manufacturing, and controlled settings to deliver real-time inventory visibility, automated fulfillment, and quantifiable efficiency. All this to enable businesses to get quicker ROIs and expandable warehouse performance. Our WMS inventory management system is capable of fulfilling below criteria's.

A ready-made Warehouse Management System (WMS) is a complete solution that is ready to handle the daily activities at the warehouse including order fulfilment, picking, packing, dispatch, and inventory tracking. In comparison to the development of a warehouse management system software in house, an off-the-shelf WMS can be implemented more quickly and has established workflows, best practices, and industry-standard functionality.

The implementation can be done within several weeks, depending upon the size of the warehouse, number of users, and necessary integrations. The core system is already developed, and thus, deploying it is not as disruptive or time-consuming as custom-developed systems, and the business can begin to realize value in a short time.

Yes. Our ready-made WMS is built with flexibility in mind. Businesses can customize workflows, reports, integrations, and user roles as operations grow or change—without affecting system stability.

The WMS is offered in cloud-based and on-premise deployment options. This will enable businesses to select the WMS configuration that will most effectively accommodate their IT strategy, security requirements, and compliance requirements.

Yes. The WMS is fully compatible with the barcode scanning system and RFID technology which allows proper tracking of inventory, faster picking and real-time awareness of all operations in the warehouse.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy