December 13, 2022

June 4th, 2025

If most are a ‘yes,’ you need a Warehouse Management System! Modern organizations must redesign their working methodologies to embed effective software solutions for smooth and beneficial operations.

Warehouse management is integral to successfully executing businesses like eCommerce, retail and FMCG, manufacturing, and more. It includes integrating warehouse functionalities with the working task force and all significant processes like sales, IT, and engineering.

This can be best achieved with a Warehouse Management System (WMS). Observing the number of WMS benefits an organization can enjoy is interesting. It is wise to invest in a good WMS and monitor work at all levels to achieve the highest productivity and reap the rewards of the WMS.

Through this write-up, we will go into the details of a WMS and explore the benefits of the Warehouse Management System.

Gartner defines a warehouse management system (WMS) as “a software application that helps manage the operations of a warehouse or distribution center (DC).” WMS is ideal for managing and monitoring warehouse operations and enhancing visibility. It handles operations like inventory management, product and stock refill, in- and out-of-stock status, picking, packing, shipping, etc.

WMS has many benefits, such as being the ideal software for effective operations, centralized supply chain management, and inventory management. It could be a standalone software or an integral part of an ERP system that works well with other modules.

What is the Warehouse Management System aimed at?

A WMS aims to simplify the complications of warehouse management by embedding it in the system to execute all daily operations of a warehouse smoothly. It also integrates all associated processes, bringing more strength and robustness to the entire warehouse functionality spectrum. WMS aims to offer better inventory and shipment precision, reduce costs, increase efficiency, and better product and material management.

Read a Detailed Case Study on: Warehouse Management App

The primary job of a WMS is to assist businesses in automating, maintaining, and monitoring their warehouses with thorough storage and workflow mechanisms. No wonder the world witnesses and enjoys many benefits of a WMSme.

It helps track all items in inventory, manage the supply chain, and generate various reports with the help of modernized technologies like RFID tags, serial numbers, barcoding, etc.

It communicates effectively with all departments in real-time to manage the entire workflow at a level that offers customers excellent service. It helps lessen costs, increase productivity, offer the latest information, and provide service.

It communicates effectively with all involved departments in real time to keep the entire workflow informed and offer customers excellent service. It helps lessen costs, increase efficiency, offer the latest information, and provide service.

Looking at the benefits of an informed system, we often wonder who the target audience would be for such a software solution. The users of a WMS could be a warehouse or a distribution center task force. Usually, I wonder if cuts need to be made to keep a warehouse for stocking and distributing WMS.

However, industry segments like manufacturing, retail, FMCG, Food and Beverage, and Healthcare are more inclined to implement WMS to better monitor their warehouse activities. Each segment has its benefits from WMS, but now, with modernized operations, it is a must.

The entire process of managing processes includes the following processes:

Many Warehouse Management System benefits attract businesses to implement them based on their needs. But each organization has its peculiarities. Based on the deployment mechanism, implementation style, and other parameters, WMS can be categorized into different types, as below:

Let’s review the benefits of the Warehouse Management System mentioned above.

Warehouses need to keep a real-time stock of all inventory items so that whenever an item is unavailable, there is no problem with orders, and it can be restocked. One of the significant advantages of the warehouse management system is that it manages and monitors inventory in real-time.

WMS is competent at tracking inventory and assisting employees in taking stock of items. They can view details regarding significant upcoming orders and replenish inventory accordingly. Problems like overstocking can be avoided, and forthcoming orders for the overstocked items can be revised accordingly.

With the implementation of replenishment, employees are sure of the benefits of a warehouse management system. They can perform their activities with ease and efficacy. Owing to automated solutions, employees can have a transparent idea about the stock and inventory levels.

Reports provide precise details about all processes and can help make crucial decisions at all levels. With the help of WMS, employees are bound to be more productive and enjoy working. From the workers to the top management, there is synchronization and collaboration between teams.

A WMS can monitor, stock, and manage inventory effectively; hence, fewer products will go to waste or be spoiled. Proper inventory management can help ensure the smooth flow of items out of the warehouse. Even over-ordering can be avoided by checking, hence, the inventory.

Implementing WMS can improve logistics tracking and monitoring. This leads to optimal product usage and, hence, less item waste. Warehouse employees will have a complete idea of what is in the inventory and in what order, and they can track the inventory status.

Like other software solutions, WMS also plays a significant role in helping users save time and money. All the benefits that WMS gets along directly impact the budgeted cost and the project deadlines involved. Errors that can be avoided or minimized directly affect cash and time. There is a reduction in the total production and processing costs.

WMS offers extensive support to employees in the areas of shipping and stocking. Users can now avoid understaffing or overstaffing, which directly affects employee turnover and revenue. Of course, detailed training is necessary for all employees; if done thoroughly, there is no looking back.

Safe and effective communication between warehouse users and customer staff is a must. Without it, there could be a lot of hassle and confusion. Instead, having a WMS could lead to complete transparency between the Safed and the client side. Both can efficiently perform their actions and leverage the necessary data for further actions.

Tracking orders, fulfilling them, getting feedback, and adhering to shipping procedures are part and parcel of WMS and will surely benefit the efficiency of clients and solution providers.

An effective WMS produces reports regularly on adhering to shipping procedures and processes in the system. This makes it easy for management to keep track of the security aspect of products. Any and every upheaval is treated promptly as per requirement, and hence, the warehouse’s and its components’ safety is regularly taken care of.

A stringent security regime is necessary, especially in high-risk categories like edible items, pharmaceuticals, and high-value items like jewelry. A warehouse management system can quickly implement such a regime.

As your business expands, warehouse management will become more complex and demanding. Implementing a warehouse software solution is the right choice to automate and streamline all involved processes for the finest results. One of the significant benefits of a Warehouse Management System is scalability.

Organizing, sure of growing far and wide, must adopt WMS with all its features to streamline all involved processes. Soon, once the business expands, those features will be helpful and easy to implement.

Customers are always looking for fast delivery of products, whether it’s a small, non-significant item or an important one. WMS is the right choice for a quick delivery schedule. The modernized tools and technologies part of WMS can significantly help speed up order execution.

The barcode scanners, item tags, barcode printing, labels, etc., used in the WMS greatly help speed up the entire order delivery process. Teams can pick up products and deliver them to the customer promptly, quickly, and accurately. WMS can ensure the least latency and time.

With automated warehousing processes, quickly and accurately apparent figures and reports regularly circulated, real-time available data stock, an effective ordering mechanism, and an efficient task force to manage and monitor the warehouse, there are few chances of any emergency conditions in the warehouse.

In warehouses where goods move quickly, customer service is crucial, and a WMS can be beneficial in ensuring that the workflow does not get disturbed in its processing and completion. Even unexpected inventory demands can be managed and moved quickly, lying at the tip of the finger through the application.

Due to the variety of reports, inventory demands the real-time information it collates; it can offer intuitive forecasting about the demand patterns that can help make futuristic decisions. Business owners find it easy and practical to study the data in reports and extract essential trends and patterns from it.

Warehouse owners can efficiently study inventory and management ratios for inflow and outflow. If extra durable products exist, they can be ordered well in advance. If some items are being underused, ordering can be stopped in time to avoid oversupply.

Traceability is vital for warehouses where products are scattered across locations. There may be times when an urgent need to find some products arises. At such times, WMS can help big time by helping trace the product through the solution. Whether barcode scanning or RFID tags, it is fast to find the product through its lot and serial numbers.

Even the reports generated from the WMS can help ensure the traceability of products anytime, anywhere. The warehouse software’s traceability feature makes managing and maintaining a warehouse easy.

A modern-day WMS offers in-depth data analytics that can be very helpful to businesses in analyzing their product delivery performance and work efficiency. WMS comes up with core metrics that provide a transparent and detailed view of the business.

Different metrics could be included, such as inventory status, sales table, revenue figures, comparison between last year and this year, reorder level, stock status, supply chain and logistics details, inventory budget, etc. These metrics can help analyze data at different levels, including wholesalers, retailers, customers, etc.

When businesses need to choose the ideal Warehouse Management System software, specific parameters must be taken care of much in advance; here:

In today’s competitive business landscape, efficient warehouse management is paramount to success. SPEC INDIA offers top-notch custom warehouse management software development services that ensure your business stays ahead of the curve.

Here’s why you should choose SPEC INDIA for your warehouse management software needs:

Choose SPEC INDIA for your custom warehouse management software development and experience unparalleled efficiency, accuracy, and productivity in your warehouse operations.

Contact us today to discuss your project and see how we can help drive your business forward.

1. How does a WMS improve inventory accuracy?

A WMS provides real-time inventory tracking, reducing the likelihood of errors associated with manual entry. It automates inventory updates with each transaction, ensuring accurate stock levels.

2. How does a WMS increase efficiency?

A WMS optimizes warehouse operations by streamlining picking, packing, and shipping processes. It can prioritize tasks and allocate resources more effectively, reducing the time and effort needed to complete warehouse tasks.

3. Can a WMS help reduce costs?

Yes, a WMS can significantly lower operational costs by improving efficiency, reducing errors, and optimizing labor. It also minimizes losses due to inaccurate inventory and poor warehouse management.

4. What kind of data and reports can a WMS provide?

A WMS can generate detailed reports on inventory levels, order statuses, employee performance, and warehouse operations. This data can be used for better decision-making and strategic planning.

5. Are WMS solutions only suitable for large warehouses?

No, businesses of all sizes can benefit from a WMS. Small and medium-sized businesses can also see significant improvements in efficiency and accuracy, which can be crucial for their growth and competitiveness.

6. Can a WMS grow with my business?

Yes, many WMS solutions are designed to be scalable, allowing you to add more features and functionalities as your business expands. This ensures that your warehouse operations can grow without needing a complete system overhaul.

7. What features should I look for in a WMS?

Key features to look for include inventory management, order management, warehouse optimization, labor management, barcode scanning, real-time tracking, reporting and analytics, and integration capabilities.

8. How can I measure the return on investment (ROI) of a WMS?

The ROI of a WMS can be measured by evaluating improvements in inventory accuracy, order fulfillment speed, labor productivity, and overall operational efficiency. Reduced errors, lower operational costs, and increased customer satisfaction also contribute to the ROI.

9. How long does it take to implement a WMS?

The implementation timeline can vary depending on the complexity of the warehouse operations and the specific WMS solution. Generally, it can take anywhere from a few months to over a year. Proper planning and phased implementation can help in managing this process effectively.

10. Are there any challenges in implementing a WMS?

Common challenges include high initial costs, staff resistance to change, data migration issues, and the need for thorough training. However, a dedicated implementation team can mitigate these challenges with proper planning, communication, and support.

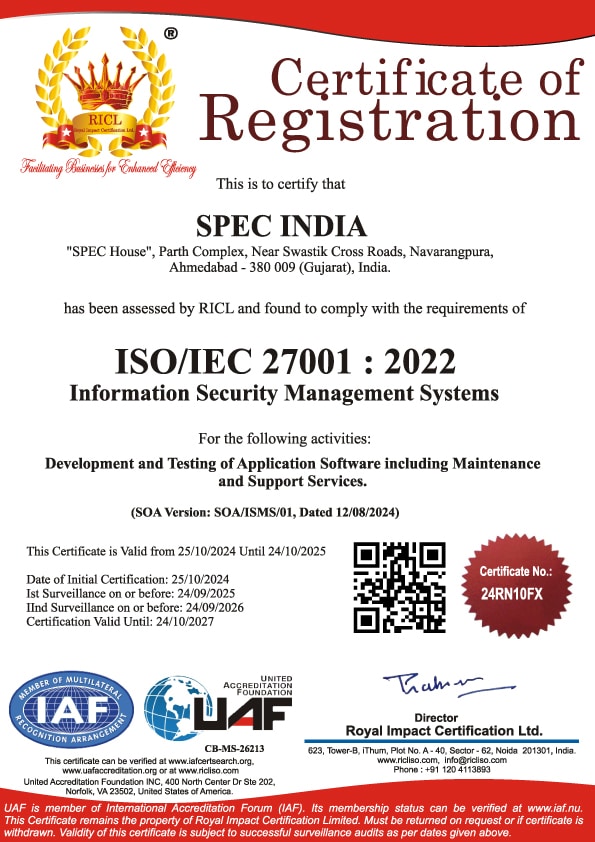

SPEC INDIA is your trusted partner for AI-driven software solutions, with proven expertise in digital transformation and innovative technology services. We deliver secure, reliable, and high-quality IT solutions to clients worldwide. As an ISO/IEC 27001:2022 certified company, we follow the highest standards for data security and quality. Our team applies proven project management methods, flexible engagement models, and modern infrastructure to deliver outstanding results. With skilled professionals and years of experience, we turn ideas into impactful solutions that drive business growth.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy