Boost your business with our custom-made ERP software development services aligned with your specific requirements. Our team better understands the industry challenges when it comes to managing resources or getting a real time visibility in everyday tasks. It is hectic!

But we are here to help you overcome these challenges. Streamline your everyday tasks like accounting, supply chain, marketing, HR tasks, procurement, sales, finance, etc, with a customizable Enterprise resource planning system that perfectly fits your business environment.

Let us help you automate your everyday time-consuming tasks so that you can manage your business with ease and confidence.

Choosing SPEC India as your ERP development company means a client-centric approach, years of expertise and experience, customization, and proven results. When it comes to ERP development, we have thoroughly researched the market and have identified that most business prefer custom ERP solutions rather than the readymade tools available in the market.

Why choose a read-made ERP system that can take more time to fit your business requirements?

Instead go with our custom ERP software development solution and get what you expect to be in ERP Software. We built solutions by considering all important business aspects and the pain points they are going through. We have professionals on the panel for designing, developing, and quality assurance for cloud-based and scalable ERP software for the management of end-to-end business processes.

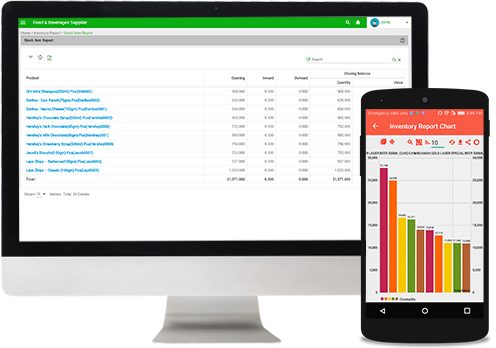

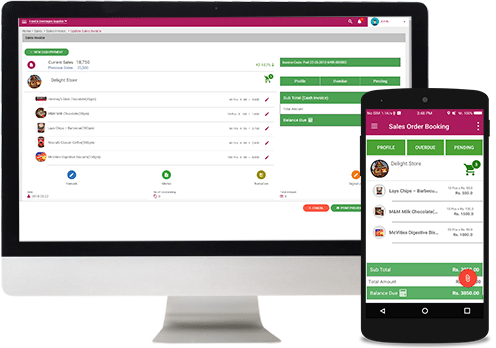

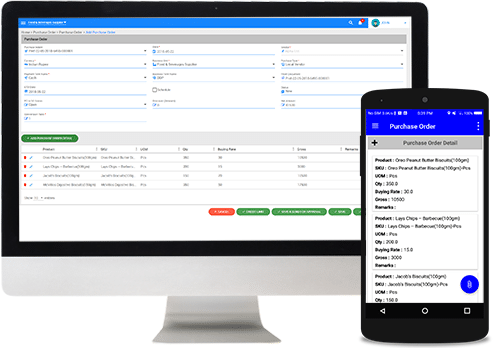

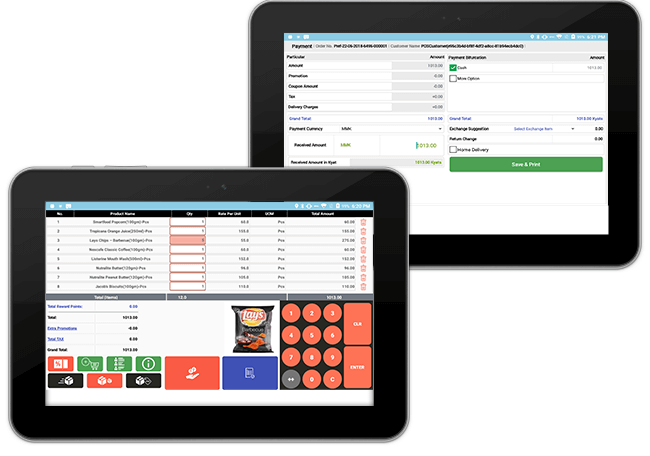

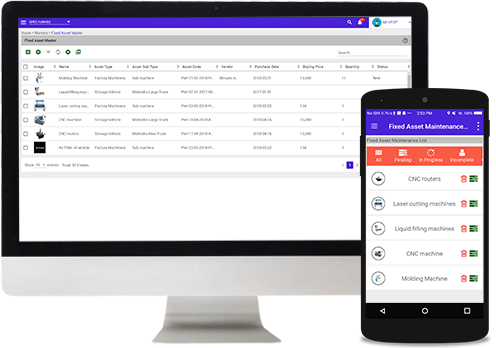

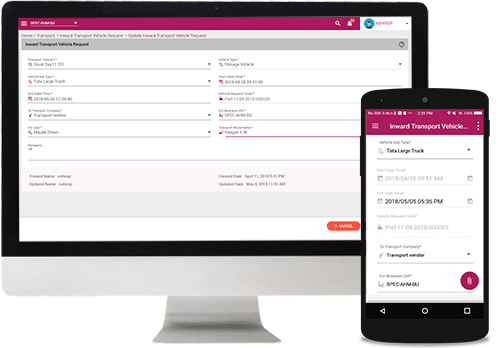

We develop cutting edge ERP software that can be run from mobile devices, desktops, laptops, tablets, smart screens or from wireless display devices making your data available to you at anytime and anywhere.

Get real-time insights on everyday data across all your departments, warehouses or distribution hubs, with our custom ERP software development services for small, medium amd large scale businesses.

Active Users

Monthly Orders Processed

Industries Covered

Consumers Served

Warehouses Covered

Dynamic Reports Generated

Customer Ratings

Ready to Use Templates

Accounts

Accounts

Human Resource

Human Resource

Advertising

Advertising

Production

Production

Warehouse Management

Warehouse Management

Sales and Distribution

Sales and Distribution

Purchase

Purchase

Point of Sale

Point of Sale

Fixed Assets Management

Fixed Assets Management

Transportation Management

Transportation Management

All accounts-related transactions are managed and controlled here. Voucher preparation, balance sheets, profit and loss statements, etc. help in efficient accounts management.

The focus of this module lies in managing and monitoring employee information, tracking employees and managing performance reviews, payroll and attendance management, etc. It also includes travel & training management.

This module seamlessly handles the media and advertisement arena of any organization.

This module focusses on different functionalities related to product manufacturing in a manufacturing unit like production planning, machine scheduling, BOM, daily progress tracking, etc.

It is meant for managing warehouse activities and tracking the stock of items in the warehouse. Managing and maintaining inventory of goods is prime. It also focusses on Warehouse space utilization, storage units, stock utilization, dashboards/reports, etc.

Managing sales effectively is the focus area of this module. Product pricing, promotions, comparison, sales targets, stock transfers, etc. are key areas.

This module provides the functionality of processes related to the procurement of materials/assets needed in the organization. Supplier/vendor details, purchase indent, quotation management, purchase orders, GRN, stock updating, etc. form the crux of this module. This module also provides the functionality of import and custom declaration.

This module is designed to offer a retail POS system for order management as per the availability of inventory. It handles online inventory handling, stock management, and order status handling.

The fixed assets module handles the recording and depreciation of company assets. It offers higher control over assets and thereby better monitoring and management of the same.

This module offers support to the transportation functionalities in the organization.

As one of the leading ERP consulting companies in the USA, we have been providing ERP development services for a decade. We are explicitly helping companies get out of their manual zones and implement automation in their time-consuming manual tasks. Transform your business with the help of our ERP solutions that can use such technologies as AI/ML, IoT, and blockchain. We do not restrict you to a specific package, our software evolves with your enterprise. As you grow, expand and add new requirements, you can call for new features to be added every now and then. Customization is limitless. Capabilities are designed to fit the company’s objectives using natural and clickable layouts for web and mobile applications. Here are some key benefits of ERP system that you can get with custom ERP development services:

With our 36+ years of experience in architecting and deploying software for various industry domains, we know how to align modern technologies with a constantly changing business landscape. :

We developed a warehouse management system for one of our Shipping and Logistics clients based in the USA. We used REST API, Spring, Core Java, and iOS technologies to develop the custom ERP solution for warehouse management. Here are the benefits our client got.

Custom ERP software development is the process of developing unique enterprise resource planning software for an organization, making it more efficient, scalable, and compatible with other systems.

ERP system implementation may require a period of roughly six months to twenty-four months depending on the project’s size, functionality, and the complexity of the company requirements.

The services provided by SPEC INDIA in the ERP field include ERP system development, implementation and mobile applications, customization and enhancement, quick ERP application development, customized enterprise dashboards, ERP migration solutions, ERP consultation and ERP maintenance.

SPEC INDIA’s ERP services encompass customisation, increased effectiveness, ability to expand, compatibility and the availability of qualified service providers for consulting, development and technical support.

Custom ERP is likely to cost between $50, 000 and a few hundred thousand of dollars in relation to the number of users, the system’s complexity and integrated features, required modules, and the time taken to develop the system.

No. Readymade ERP software solutions cannot be customize as per your requirement.

Before building ERP software, ensure clear requirements, stakeholder involvement, reputable vendor selection, scalability and flexibility, integration needs, realistic budget and timeline, and plan for user training and ongoing support.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy